High tensile bolt connections are used on tower crane joints including those on mast jib and slew ring bearings. Every bolt on a tower crane has a specific torque value and its the crane owners responsibility to ensure each bolt is torqued to that value with a calibrated wrench.

Tower Crane Bolt Torque Critically Important For Owners And Operators

Every bolt on a tower crane has a specific torque value and its the crane owners responsibility to ensure each bolt is torqued to that value with a calibrated wrench.

Tower crane bolt torque. This common practice of loosening de-torquing mast bolts to finger tightness or less prior to dismantling and or climbing a crane down and also during assembly is. The tightening torque is applied to the nut rather than the bolt head unless the manufacturer specifies otherwise. Tightening a bolt at the head can give rise to variability in bolt pre-loading as.

Bolt And Nut Failure At The Slewing Ring Of The Tower Crane Figure 1. And because tower cranes can be so large and complex in their construction it may take multiple torque wrenches to correctly tighten each bolt. Some will de-torque all tower mast bolts to the point that they can be removed by hand and then climb down andor dismantle the crane.

A possible loss of torque due to the material elasticity can thus be avoided. In a user guide specifically for this crane model SAEZ recommends elec-tric or hydraulic torque multipliers and re-fers to alkitronic products. Find here an overview about bolt connections on construction cranes rotating tower cranes and offshore cranes and their relating tension and torque tools from ITH.

It is safe to lift 155t at the cranes maximum reach. Others will continue climbing when hydraulics are leaking or. Some disconnect limit switches to pull up or lower a climber.

The incident took place when the crane operator was starting to lift the waste container at level 1 and move to the nearest area. The user guide recommends that all tower bolts be retightened after the crane has been in operation for two or three days. The nominal torque for this model is 2000.

And due to the size and complexity of tower cranes you may need multiple torque wrenches to apply the correct torque to each bolt. When correctly installed and pre-loaded high tensile bolt connections can. The challenge was to find the best tool and the ideal method for bolting all the connections of.

Worthton 2005 - A Wolff 320BF Luffer tower crane collapsed into another crane during dismantling. It has been sold without Cross girder Undercarriage and Rail carrier as of 2013. With this crane it is possible to reach a height of 68m with the hook.

These parameters will fundamentally impact the cranes safety during operations. For lifting a load this Liebherr crane is equipped with a 37kW hoist unit. Hydraulic electric manual and pneumatic torque wrenches might all.

The tower crane must have a device that prevents moment overloading. Tower sections are used to make cranes tower mast and theyre like trusses. Tower cranes require frequent assembly and disassembly which is why proper bolt torque on these machines is vital.

Grade 109 hex bolt scm435 material for tower crane. On Thursday 27th August 2015 at around 930am an incident involving tower crane has occurred. The requirements are the bolting of M70 stud bolts using the SAEZ method with 7200 Nm.

The crane model from SAEZ lifts and can move up to ten tons. Tower Crane At the Accident Area. They are subject to repeated cyclic loading as the crane lifts and lowers loads and slews.

And due to the size and complexity of tower cranes you may need multiple torque wrenches to apply the correct torque to each bolt. A radius indicating device must be used if the tower crane is not equipped with a radius indicating device the radius must be measured to ensure the load is within the rated capacity of the crane. 2 Deaths 1 Injured.

The applications are for example the slewing bearing steel construction corner bar foundation bolts counter weight fixation and more. Every bolt carries a specific torque value meaning the crane owner must ensure each bolt is torqued to the appropriate value with a calibrated wrench. Filmed in Dublin in conjunction with Lewis Tower Cranes and John Paul Construction using Norbars EvoTorqueErecting a 56 metre high tower crane on a constru.

The 112 EC-H 8 120 HC is manufactured and distributed with Cabin and Climbing device. Sections are bolted together Bolts and pins are secure connections for any crane and they should have higher tensile strength to withstand torques and considerable important dangers. The nominal torque for this model is 1120.

Tower Crane Blackbox as a Service provides capabilities to collect and process key crane performance parameters for example weight height radius rotatory angle wind speed and other critical parameters. In addition the weight of the load must be determined from a source recognized by the. With this crane it is possible to reach a height of 388m with the hook.

Frb Bearings Co Ltd How To Maintain The Tower Crane Slewing Ring Here Are 9 Points For Reference

Tower Crane Bolt Torque Critically Important For Owners And Operators

Xcmg Xgtt200 Crane Load Chart Specs 2017 2021 Lectura Specs

Assembling Tower Crane Sections With A Hydraulic Torque Wrench Enerpac

Self Erecting Tower Crane Reliable Simple And Safe

Tower Crane Safety By Khalid Issuu

Seattle Tower Crane Collapse Questions About Disassembly Procedures

Sany Syt63 Crane Load Chart Specs 2020 2021 Lectura Specs

China 10 9 Grade Mast Section Bolts Pins For Tower Crane Section China Bolts For Tower Crane Mast Bolts

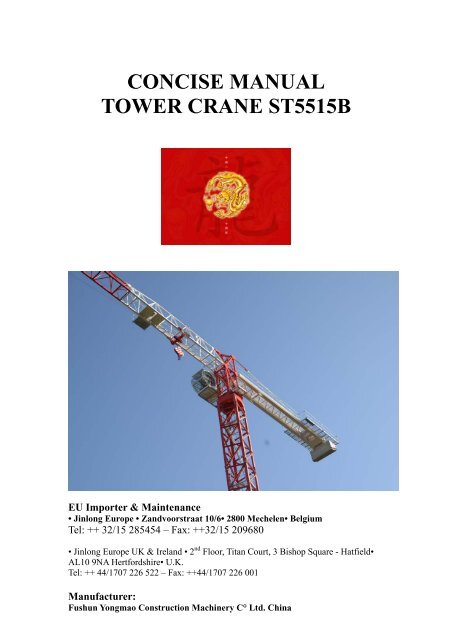

Concise Manual Tower Crane St5515b Jin Long

China 50 Ton Large Tower Crane For Power Station China Power Station Constuction Machinery

Electric Torque Wrench For Crane Assembly Gedore Lew 60l

China High Quality Tower Crane Construction Bolt With Washer China Tower Crane Bolt Construction Bolt

Ciria Report C761 Tower Crane Foundation And Tie Design Graham Garner Partners Occupational Safety And Health Risk Management

15 Ways To Help Ensure Tower Crane Safety

Tower Crane Bolt Torque Critically Important For Owners And Operators

Official Website Department Of Occupational Safety And Health Bolt And Nut Failure At The Slewing Ring Of The Tower Crane